Scalable Automatic Modal Hammer (SAM)

The knowledge of the dynamic properties of a structure (natural frequencies, damping and mode shapes) are necessary to develop products that are characterized by their light weight and low noise emission. Currently, there are insufficient usable parameters for tolerances regarding acoustics and vibrations, for the development and quality control of a product or system. This downside causes considerable costs for manufacturers.

With the assistance of SAM, it is possible to automatically measure the dynamic properties of components such as brake pads, gear motors, shafts of small gear motors etc., and precisely reproduce the same results. This is primarily necessary for the development of low-noise products which leads to the development of specifications that guarantee a rugged and low-noise product in mass production. The SAM thus creates the conditions for the commercial implementation of the measurement method "automatic modal analysis".

Comparison with existing solutions:

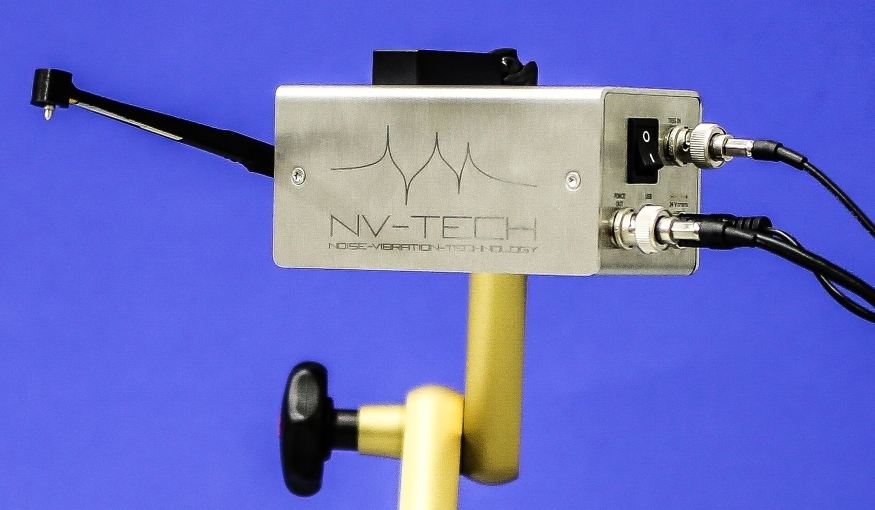

The unique SAM design has the ability to control via GUI (graphical user interface) the dynamic of the hammer handle. By controlling the dynamic in terms of accelaration, deceleration and stopping angle it is possible to adjust different force excitation levels with high accuracy and repeatability. This variable force adjustment is essential to approach different operating points in the spring characteristics. In order to avoid possible damage to the surface of specimens, an exact adjustment of the impulse force is absolutely necessary. The advanced construction of the SAM with the stepper motor control enables setting up an exact force that can be used for exciting the structure precisely at the desired point, in all spatial directions possible. The measurement in all three spatial directions is important if you have to perform experiments on motor vehicles or airplanes directly at the place of installation. The ability to measure in all three spatial directions is not possible with other known solutions. The automated hammer is also superior because of its compact design as it does not require an external control device.

The SAM is available in two sizes – SAM 1 and SAM 3

Specifications of the SAM 1

Input voltage hammer: +24 V

Constant current: 2 A

Max. impulse force: 200 Npk / 50 lbfpk

Impulse force range: 10-200 N ± 4 N (*)

Frequency range: 0 ~ 20 kHz (*)

(*) Values depend on the test material

SAM1

Specifications of the SAM 3

Input voltage hammer: 24 VDC

Constant current: 2 A

Max. impulse force: 2200 Npk / 500 lbfpk

Impulse force range: 10 - 2200 N (*)

Frequency range: 0 ~ 10 kHz (*)

(*) Values depend on the test material

SAM3

.

| Typ | Specification | Size |

|---|---|---|

|

20191008_Specifications_EN.pdf | 1.915 KB |